Processes.

Processes.

Processes.

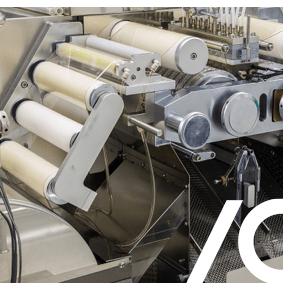

Paper and board production is water-intensive. Expensive chemicals, such as chlorine, are used in the bleaching of paper. Pollution of water supplies can attract significant penalties. The heat needed for drying paper pulp requires a lot of energy.

Constant monitoring of materials and processes in real-time ensures legislative compliance and control of waste and excess consumption. Process transparency enables the optimisation of employee activity and of jobs and machinery.

Moving Towards Greener Manufacturing