Job Shop

Job Shop

Job Shop

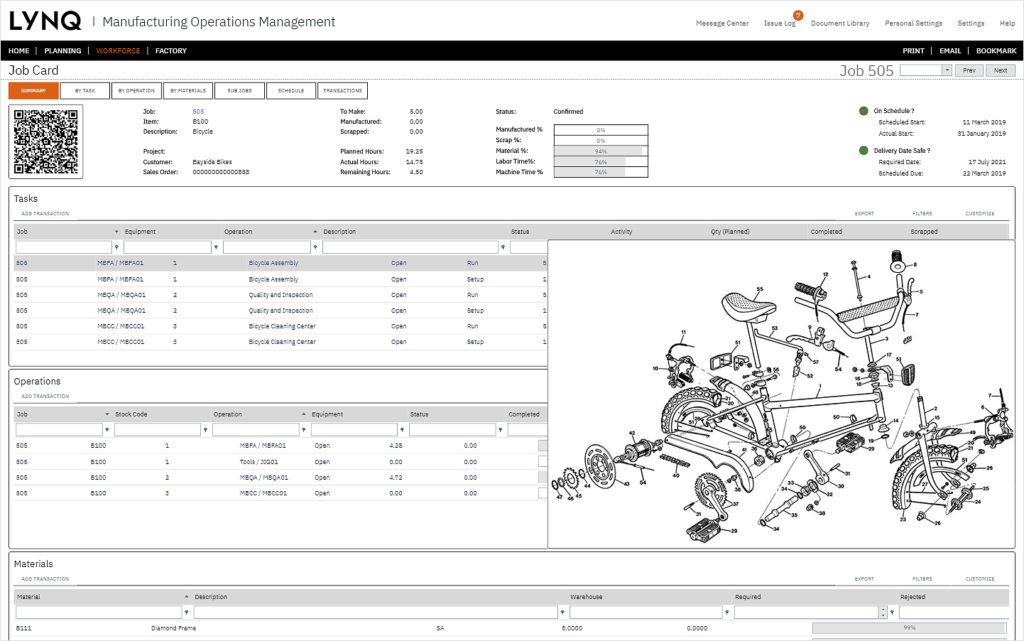

Custom product/ one off

Design > Calculate > Quote > Source > Make > Deliver

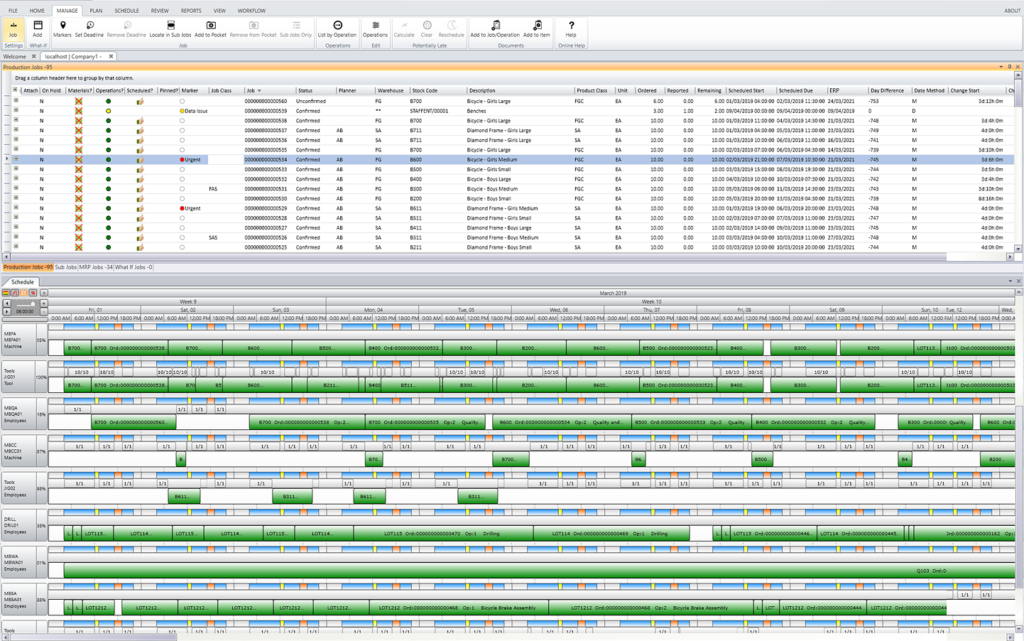

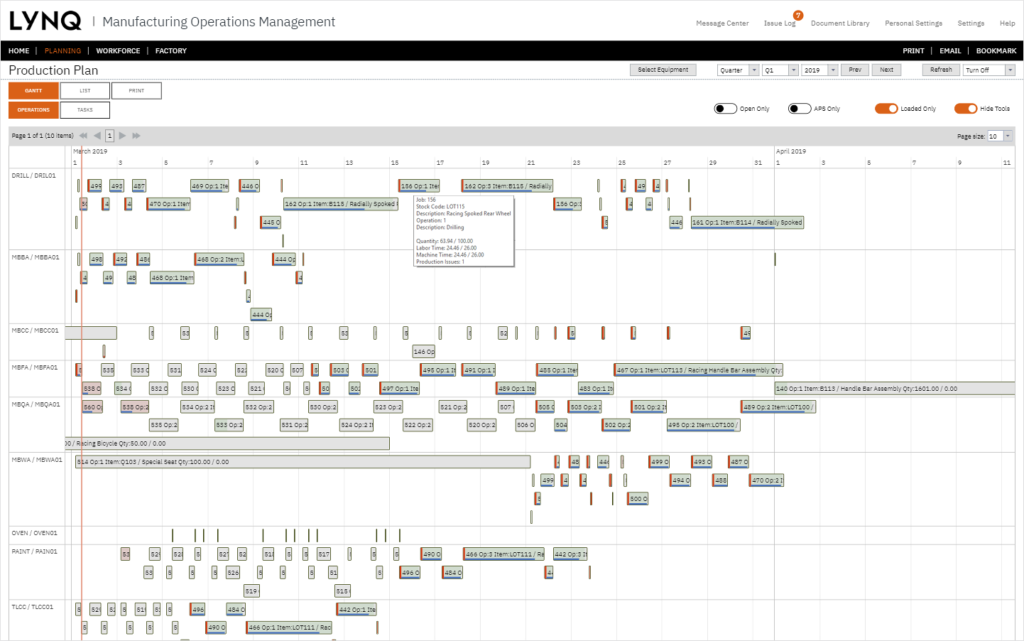

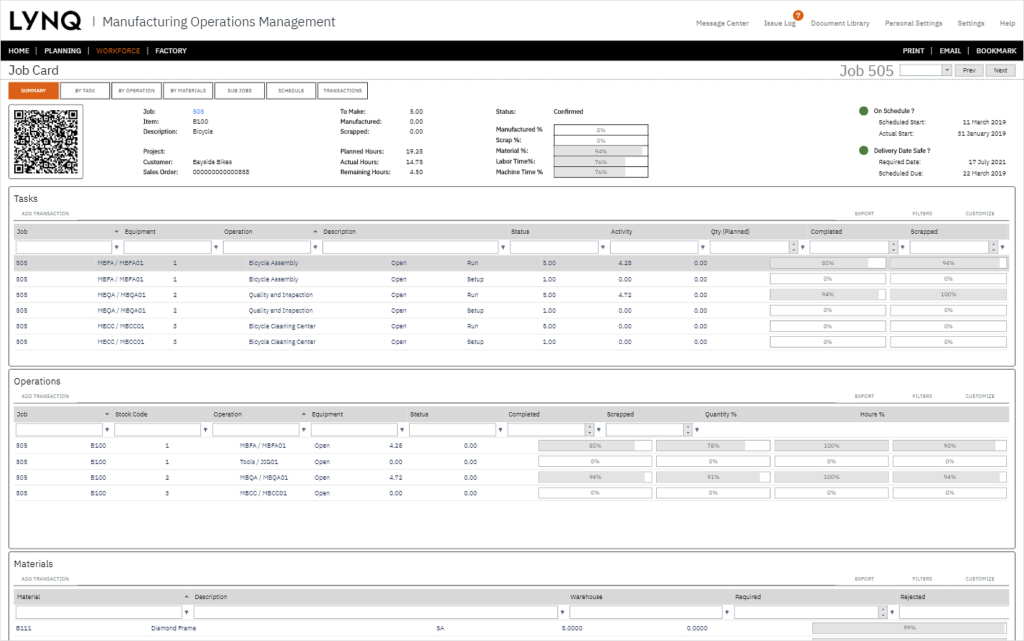

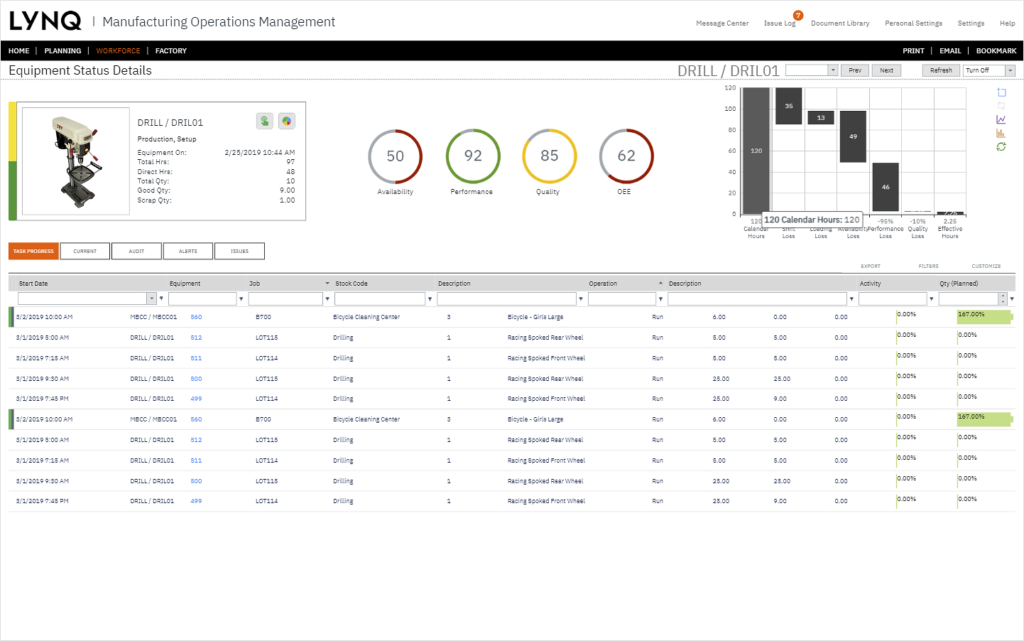

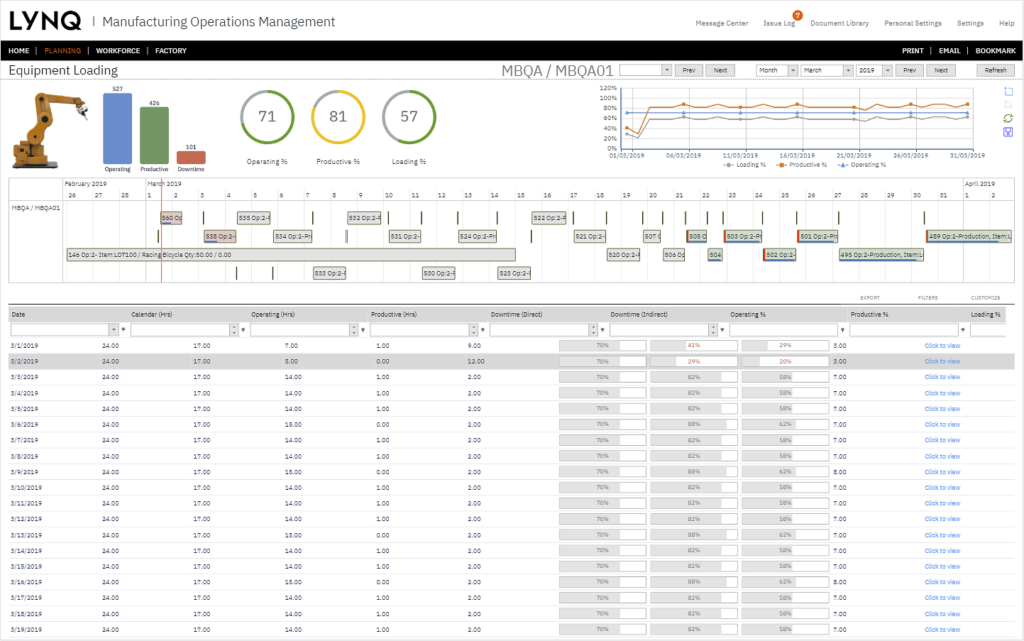

- Capable to Promise – ability to determine the delivery date of potential orders by overlaying them on the existing plan

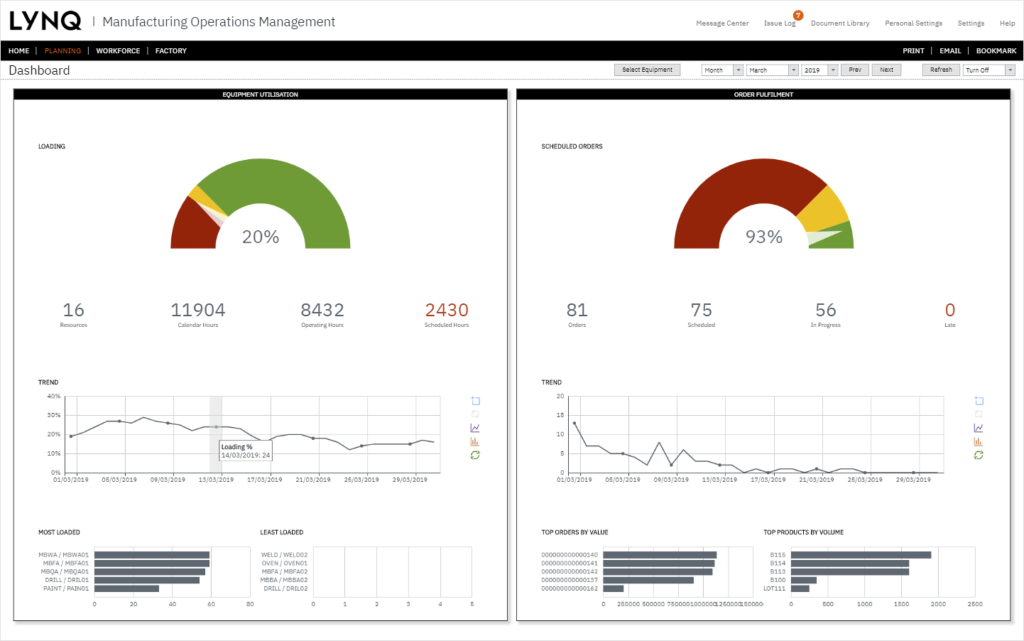

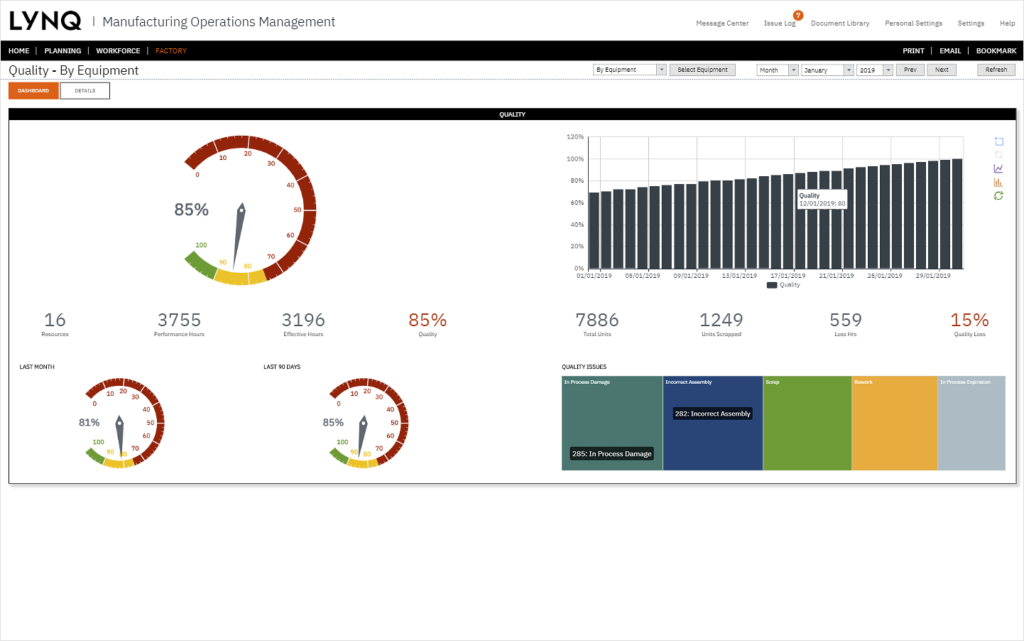

- Accurate job costs – ability to collect data easily and accurately to determine accurate job status and costs for margin and/or profit analysis

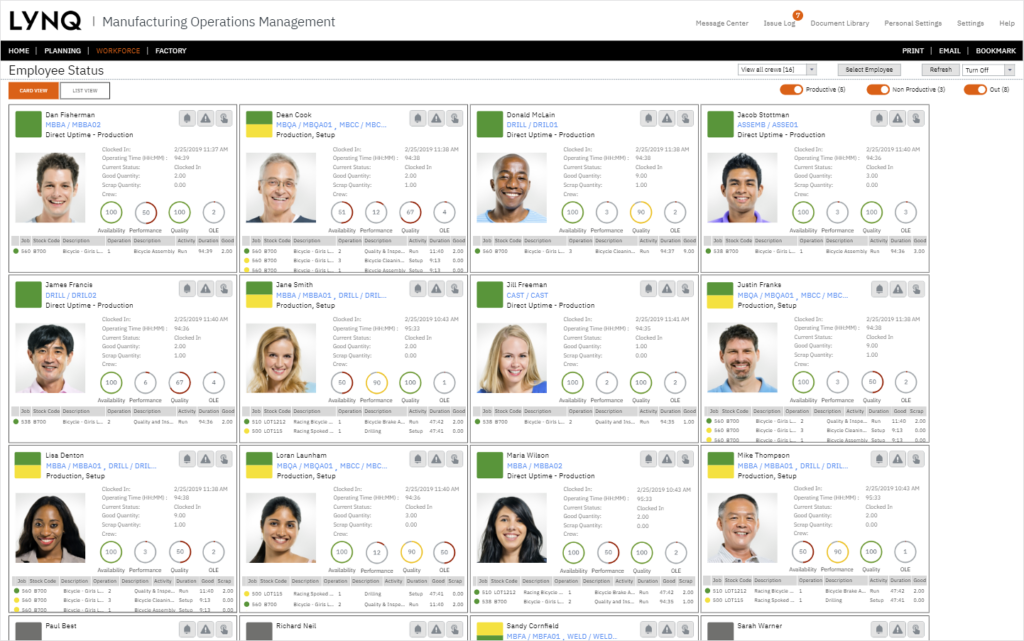

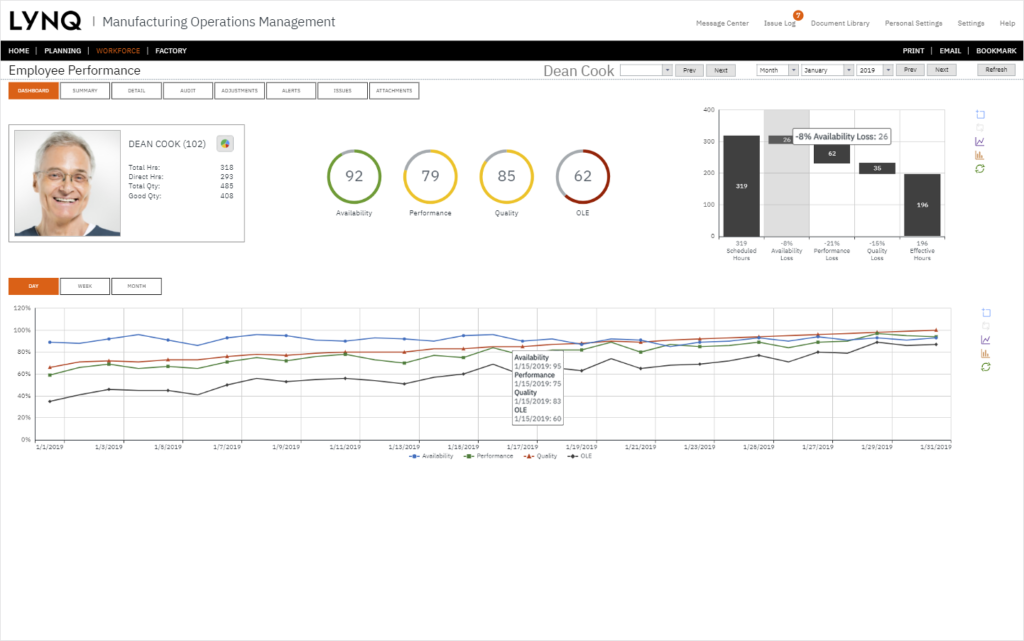

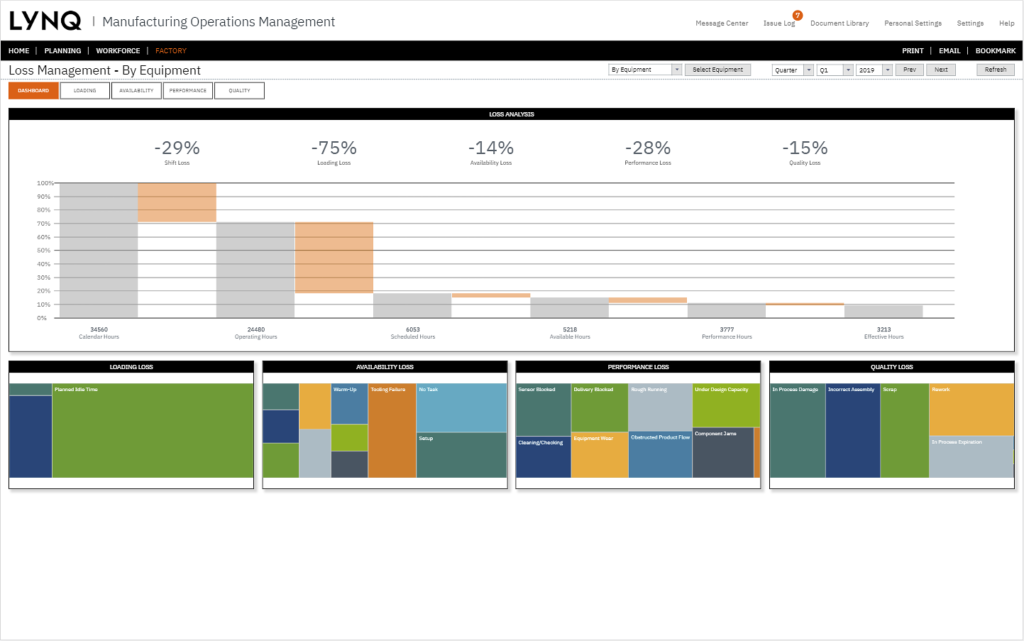

- Employee utilisation – ability to analyse and make best use of high cost, skilled employees (OLE)